Our team of skilled engineers has decades of experience in steel fabrication, and we pride ourselves on delivering exceptional results for our clients. From custom architectural steelwork to precision machining, steel erection and welding, we have the expertise to tackle even the most complex projects.

We use only the finest materials and cutting-edge technologies to ensure that our products are of the highest quality. Whether you need structural steel components for a building project, customized machinery, or decorative metalwork, we can create the perfect solution to meet your needs.

We are committed to providing exceptional value to our clients, and we strive to maintain competitive pricing without compromising on quality as well as delivering quick turnaround times, ensuring that your project is delivered on time and on budget.

So whether you’re in need of a single custom steel component or a complete steel fabrication project, our team is here to help. Contact us today to discuss your needs and discover why we’re the leading steel fabrication company in the Southwest.

The Story

About

Established

Established in 2010 we have vast experience in a wide range of projects in all sectors, including Commercial, Industrial, Housing, private builders & developers.

The Story

About

CE Marking Execution Class 2

DMI achieve CE marking execution class 2

The Story

About

Over £1M Turnover

Turnover reaches and exceeds 1 million and employee’s increase to 8 in the workshop and 2 full time office staff.

The Story

About

Investments

DMI invest in advance steel detailing and new delivery truck to cater for an ever increasing workload.

The Story

About

Expantion

Second workshop / trade counter opened for public and trade.

The Story

About

Higher Goals

Year starts with a strong order book with turnover look set to reach 1.5 million and further investment imminent in the near future.

What we do

Our Range

Welded to bottom of a column or post to allow fixing to a foundation or concrete pad.Normal practise to allow a gap to the underside for dry packing / grout.

Bolted at intersection with one beam notched with a welded end plate – where beams are different depths these can be flush top or bottom to suit your site requirements

A beam end cut to match the pitch of a roof timbers.

Can be fixed to either one or both sides of a beam, used to support metal decking or pre-cast concrete floor planks.

Supplied either loose or welded to beam to spread load bearing at each end.

A pair of beams joined together used where height may be restricted. Beams are bolted together with either tubular or PFC spacers.

A splice for connecting two lengths of steel to aid carrying / installation. This is not a full splice and will have to be agreed with an Engineer.

Bolted at intersection with end plates, possibly with a stiffener plate behind – where beams are different depths these can be flush top or bottom to suit your site requirements.

Used to split beams into shorter more manageable sizes, can be used with HSFG bolts.

Bolted at intersection with end plates, possibly with a stiffener plate behind – on different beam sizes these can be flush top or bottom to suit your site requirements.

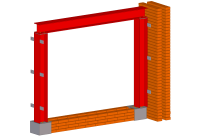

A typical Mansard type roof frame, typically supplied in smaller component parts for ease of erection.

A compound beam used in house construction, the flitch plate is pre-drilled and then sandwiched between two timber beams on site, the three layers being held together with bolts.

Steel used as the main material for making structural steel shapes.

Range of Beams & Measurements

Stock Range Available

Whatever building project you’re undertaking, we can fabricate universal steel columns in a range of sizes to meet your requirements. And if the size you need isn’t listed, we’ll be happy to discuss measurements with you.

We’re able to provide steel parallel flange channels in the size you need and at a time to suit you, even if it’s within a few hours. You can rely on us to fabricate, supply and deliver products that are suitable for your needs.

The steel angles we fabricate are available in a number of different sizes, all of which can be delivered to and installed on your site within a few hours. Therefore, you can fully rely on us to produce angles that are ideally suited to your building project.

Circular Hollow Sections, or CHS as they are commonly stylized, are the original and most consistent hollow section since its inception.

Circular Hollow Sections, or CHS as they are commonly stylized, are the original and most consistent hollow section since its inception.

Whatever size you require, our universal steel beams are fabricated to our exacting standards and delivered and installed within just a few hours. That way, you can be confident that you’ll receive the very best service from us.