Zunum Aero, a hybrid-electric aircraft startup with financial backing from Boeing and JetBlue Airways, just announced details about its first planned aircraft and a timeline for development. Zunum hopes to start selling a 12-passenger commuter plane with hybrid-electric propulsion by 2022, according to Aviation Week.

The aviation startup, headquartered in Kirkland, Washington, has been quietly working on aircraft designs for some time. In April, Zunum announced plans to build a wide range of hybrid-electric planes to provide fuel-efficient flight, especially over regional routes. The company hopes to have a fleet of electric planes ranging from 10 to 50 seats by the end of the 2020s.

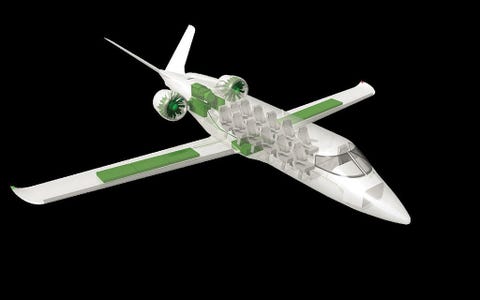

The planned 1-megawatt hybrid-electric propulsion system would use a 500 kilowatt turbo generator that burns jet fuel to charge a modular battery system. Batteries integrated into the wings could either be recharged on landing or swapped out for quicker turnaround, something Matt Knapp, Zunum Aero CTO and co-founder, called "a great design challenge." The hybrid-electric system would power a motor to drive twin ducted fans.

"It is roughly the size of a [Pilatus] PC-12, maybe a bit bigger with the ducted fans," Knapp told Aviation Week.

Based on estimates using energy densities currently achieved in lithium-ion batteries out of Tesla's Gigafactory, Zunum projects its first aircraft will have a maximum takeoff weight of under 12,500 pounds, a range over 700 miles, and a cruise speed of 340 mph. The batteries, which can be swapped out and updated as new technology is developed, would take up about 20 percent of maximum takeoff weight. For short regional flights, in the 300 to 500 mile range, Zunum says their first commuter plane would operate at a cost of eight cents per seat mile, or 3 to 5 times cheaper than a similar sized aircraft like the PC-12. It would also carry only 800 pounds of jet fuel compared to the PC-12's 2,700 pounds.

Zunum is planning to develop the propulsion system in house, but the startup is looking for a contractor to design and build the airframe. It is not clear if Boeing will assist with airframe manufacturing, but Knapp said his company is "looking for potential partners." Zunum also put out a request for information to manufacturers for the turbogenerator, while the company will design and build the motor in their own factory. Once the powertrain is completed, Zunum will test it on a converted aircraft in flights scheduled for 2019. The final step would be to integrate the electric propulsion system with a new airframe design.

In addition to providing fuel-efficient flight and reducing aircraft noise, Zunum is betting that its new hybrid-electric planes will reinvigorate the regional airline market of flights that are less than 700 miles. By driving operating costs down with hybrid-electric technology, a12-passenger plane operating out of small airports would become a viable option for many passengers flying routes from San Francisco to Los Angeles, for example, a flight that Zunum told theGuardian would cost $120 one-way. The reduced speed of the hybrid-electric propulsion would be mitigated by cutting down on passenger travel time spent in lines and security at larger airports.

Electric flight has proven incredibly challenging, primarily due to the energy density of batteries not making up for the added weight in the aircraft. But as battery technology plods forward, and hybrid-electric systems become more sophisticated, planes with batteries are starting to look like an inevitability.

Source: Aviation Week